Solar: Difference between revisions

| Line 107: | Line 107: | ||

===Installation Guidelines and Considerations=== | ===Installation Guidelines and Considerations=== | ||

We spent 4yrs living full time in an RV with a 400W array of solar panels and 4 golf cart batteries connected into a 12VDC battery bank. A substantial part of our time was spent living off grid or boondocking as the RV'ers like to call it. We attempted to maintain our batteries using the procedure recommended by the company president that made the charge controller we had and 2 years later we had 4 dead golf cart batteries. We thought we'd done everything humanly possible to make them last for 6-10yrs and suddenly realized something was very wrong. Eventually we discovered that solar equipment manufacture marketing is light years ahead of their engineering for most companies and installers. | |||

Solar installations run at low DC voltages and high currents unlike the 120/240VAC found in most homes. That means little voltage drops due to small wire size or poor connection can really add up fast to sap the energy you're getting from those panels. In addition, we discovered charge controller manufactures are worried about being sued by folks who don't maintain their batteries so they set the absorb charging voltage to around 14.3-14.4VDC. Battery manufactures will tell you 14.7-14.8VDC absorb voltages are required to maintain a 12V battery. That little 0.4VDC difference may not sound like much, but it had destroyed our batteries in only 2yrs. The voltages don't cause sulphates that percipitate out of solution to be driven back into solution. Over time they build up at the bottom of each cell and destroy it. You'd think installers would know all this and set the charge controller up to charge at the higher voltages, but sadly most are only interest in separating you from your money as quickly as possible and all that setup stuff takes time they could be spending separating the next customer from their money. | |||

Fortunately, we met up with a fellow fulltime boondocker and solar expert named Bob who helped us sort out the mess. Turns out poorly designed or manufactured components, along with shoddy installation practices is so common in the solar industry that Bob had made a full time job of cleaning up other installers messes. The fact that our batteries were history after only 2yrs was a sure sign we'd been constantly undercharging them and Bob recommended a reliable cost effective replacement for our charge controller. He told us to get new batteries in Yuma and meet him at his work site in the middle of the desert. Turns out the batteries were wired incorrectly, one of the wires connecting the panels to the batteries hadn't been tightened and the long wires between the batteries and the charge controller was inducing addition undesirable voltage drops causing yet more under charging. Bob added a battery monitor to our system, redid the wiring, replaced the charge controller and hooked the batteries up correctly. The whole process took about a day of his time and it's all been working for 6yrs now. If you're interested in Bob's blog where he goes over the pitfalls he's uncovered over the years and the components he's been impressed by, take a look at http://handybobsolar.wordpress.com/. | |||

So I'll try to summerized some of the things I've learned about solar from guys like Bob. I'm sure my list isn't exhaustive by any means, but many of these things came via the school of hard knocks. | |||

#Make sure your system is charging your 12V batteries for an hour or two each day at 14.7-14.8VDC during the absorb portion of the charging cycle. Scale this up for 24 and 48V systems. | |||

#Make sure your charge controller is mounted as close electrically to the battery as reasonably possible. Long wires between controller and batteries will create voltage drops preventing the batteries from seeing 14.7-14.8VDC. If long wires are required somewhere in your system, put them between the solar panels and the charge controller. | |||

#Make sure wire sizes are large enough to minimize voltage drops in your system. For example, the system in the preceeding section uses a 300W inverter to produce 120VAC. A 1V drop in a 120V circuit do to poor wiring is undesirable, but certainly not the end of the world. But in order for the inverter to produce 300W of 120VAC driving a 2.5A load, it has to extract 25A from your 12VDC battery. A 1V drop in the 12V portion of the circuit would be devisating and represent a power loss of almost 10% wasted in wiring. Worse, it could also cause excessive inverter heating and might even cause the inverters low voltage protection to shut it down. Web sites like http://www.csgnetwork.com/voltagedropcalc.html and http://www.cossin.com/page4.html can be used to evaluate wire sizes. But remember, their standard is for not creating a fire hazard, not minimizing voltage drops. Consider their recommendations as the absolute minimum sizes to prevent fires. Not what you should be using. If their site indicates large voltage drops at maximum currents, experiment with increasing the wire size until more managable voltage drops are idicated. | |||

#Make sure your system has a battery monitor like the one in the previous section. You can do serious damage to your batteries if you don't know what's going on with them and you should never discharge them below 50% of their capacity if you want them to last. If you don't know what the current percent of charge is, how are you going to tell when you're getting close to 50%? | |||

#Make sure your batteries are connected properly. There is a right way and a wrong way to configure 4 golf cart batteries into a 12V battery bank. The correct way is shown in the following figure. Notice how current has to go the same electrical distance through the battery bank no matter which battery it goes through. If you don't do this, batteries on the short path will be constantly overcharged while those on the long path will get undercharged. Over time, the long path undercharged batteries will die. | |||

#Another question to consider, is where to mount your panels? This might seem a simple matter, but unless you're blessed with limitless open spaces, shaddows can be a big problem. Our property has lots of trees and we had to study the shaddows for an entire year (through all 4 seasons) to figure out where to mount them. The cabin is surrounded by tree, so that wouldn't work and winter tree shaddow made the choice look like mission impossible. But eventually we realized that if we could get them off the ground far enough the north edge of the clearing near the cabin would work. So we built a small tall barn and mounted the panels on the roof. This also allowed us to make sure the side of the barn was perfectly aligned with north and south. And I'm not talking about magnetic north/south. I'm talking about true north that one discovers by finding the North Star in the night sky. | |||

#Even small shadows can be a big problem. Something as insignificant as a radio arial shadow can shut a panel down. If you have panels in parallel, this might result in slightly low solar output as the remaining panels are left to carry the load. But if they're all in series, one shaded panel can shut the whole string down. | |||

#Panels can be wired in series or parallel if you have the correct controller. Serial connections usually requires an Maximum Power Point Tracking (MPPT) controller, which acts as a DC-to-DC converter to match high panel voltages to lower battery voltages. The advantage of serial panel connections is that it increases the voltage applied to the controller and reduces the current required to achieve the same power level. Reduced cable currents helps minimize voltage drops in the system and can allow you to use smaller gauge wiring. The panels on our barn are wired with four panels in a row, then each row is connected in parallel. This provides around 120DVC to the charge controller when the sun is shining. If you're using high voltages like this, be careful because touching it is at least as bad as sticking your finger in an electrical outlet. | |||

#Once you know where your panel will be located, there's the question of what angle to mount them at. That is unless you have the financial resources to employ sun tracking, which few do. The simple answer is they should be tilted up to match your latitude if you want optimum performance on the solar equinox. The latitude of our property is 45°, so one might suspect that's the angle we chose for our barns' roof. But the optimum angle changes with the season. It's 15° lower at the suns' high point in summer and 15° higher during the shortest day when the pagans celebrate the birth of the sun god. While summer days are long with lots of sun, winter days are rather short with limited opportunities to collect sunshine. We chose an angle slightly less than 60° for our roof pitch to give us the best chance of getting a full charge on those short winter days. During the summer, long daylight hours more than make up for the losses due to poor angle choice. But even with the optimum winter angle, we still find we have to run our generator 6-7 times each winter to make it through those period when cloudy skies for days on end exhausts our battery bank. So for folks who have to rely on solar for winter power, I recommend they mount their panel a little less than their latitude + 15° to optimizes winter performance. | |||

#Now that you know where to mount your panels and at what angle, you might want to think about what you're going to do when it snows if you live in that part of the country. Sure, the snow will eventually melt and allow you to charge your batteries, but can you stand the loss of battery charging time during the shortest days of the year. We couldn't without a lot more generator time, so we built a catwalk on our barn to knock the snow off first thing in the morning. Make sure you know what you'll do when it snows. | |||

#All batteries require periodic attention if you're going to maintain them and flooded lead acid batteries have to be refilled with distilled water. We do this quarterly for our RV and every other month for our cabin system. Maintenance should only be performed when the batteries are fully charged, as refilling uncharged batteries can cause them to overflow when they're brought up to full charge. It's a good idea to check the acids' specific gravity to make sure all cells are reaching the same state of charge. Wildly fluctuating readings indicate your batteries may need to be equalized. If this doesn't help, your batteries may be going bad. Make sure you clean up any battery corrosion while you're servicing them. | |||

#Batteries contain hazardous chemicals and create hazardous gases so they need to be kept in a vented location where they won't cause damage. For our RV there's in a compartment with a metal grating under them to allow free flow of air. We built a fiberglass lined wooded box for the ones in our cabin with a tight lid. We drilled a hole in the lid and have a 2” PVC pipe to allow battery fumes to vent up the pipe to the outside of the cabin. The pipe has to be removed before we can perform battery maintance. | |||

A final installation note. Modern charge controllers, battery monitors and inverter/chargers all have processors in them that have to be configured for you specific installation needs. Don't just assume the manufacture set them up the way you need them. You have to program them. | |||

===What to do when the Sun don't Shine=== | ===What to do when the Sun don't Shine=== | ||

Revision as of 06:44, 2 January 2016

Solar has to do with the sun.

There are numerous ways to collect energy from the sun.

Solar Electric

No one does solar to beat the power company. Usually the reason someone puts in solar power is because they cannot get power in a particular place that needs some low voltage or they want some power that is renewable and reliable when there is nothing coming from the power company.

There is so much hype out there it is hard to tell what is the best deal. What would be nice is to find the best deals that makes the most sense for a particular need without having to become an electrical engineer or test two products we can't afford to find out we should have bought the third product we did not know about.

So much of our modern lives is dependent on electricity. What will we do when the power goes out for an extended period of time? Having even a little light when all other lights go out in the middle of winter could make a big difference in the mental state of a household. If part of your food preparations include frozen food, a backup source of power for the freezer could be very valuable. This article is intended to be an introduction to the possibilities of solar electricity for your household.

If you have questions about solar electric, sign up for the HHCPOWER Google group and post a question.

Terms and Definitions

Solar panel – creates electricity from sunlight

Charge Controller – uses electricity from solar panel to charge batteries. The charge controller protects the batteries by ensuring that the batteries are not overcharged

Inverter – Converts battery DC electricity to AC electricity that most appliances use

Electricity – the movement of electrons through a wire

- DC electricity – direct current electricity

- AC electricity – alternating current electricity

Volts – the force pushing the electrons

Amps – the amount of electrons moving through the wire

Watts – a unit that is a measure of electricity doing work in an instant of time. Watts is sometimes referred to as power.

- Watthour – one watt of electricity doing work for one hour

- Kilowatt hour – one thousand watts of electricity doing work for one hour. Your home electric bill says how many kilowatt hours you use each month.

A light bulb in your house may be rated at 100 watts. Burning that bulb for four hours uses 400 watthours or .4 kilowatt hours.

Basic Solar System

I consider a solar system one might use to live off grid in an RV to be the minimum most folks would want to live with. Such a system would only be able to power a few essentual items in most houses, but we lived in an RV for 4 yrs after we retired and the following system is what I'd recommend after learning several lessons the hard way. It's not exactly the system we have, but represents a cost effective design I wish we'd started with, rather than what we slowly evolved to via the school of hard knocks. Much of the information we learned along the way was care of Handy Bob Solar, who can be found on the web at http://handybobsolar.wordpress.com/.

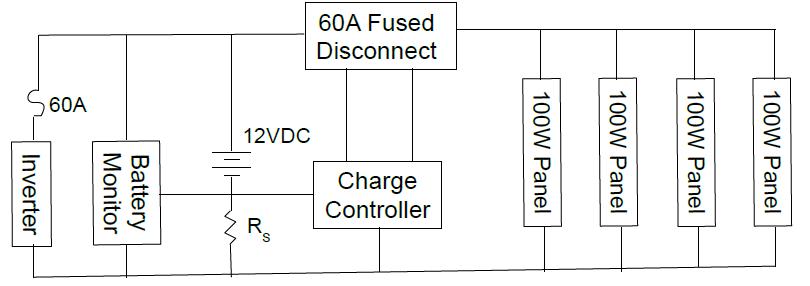

The electrical diagram for this system is shown in Figure 1 and is composed of the components listed in

Figure 1. Solar System Electrical Diagram

| PCs | Description | Price |

|---|---|---|

| 1pc | MorningStar SI-300-115V -UL SureSine 300W Inverter, 115V, 60Hz | $251 |

| 1pc | Morningstar TS-45 TriStar 45 Amp Charge Controller 12-48V PWM | $150 |

| 4pc | Windynation 100 Watt Polycrystalline 12V Solar Panel | $524 |

| 4pc | Trojan T-105 6V 225Ah Flooded Lead Acid GC2 Deep Cycle Battery | $600 |

| 1pc | Bogart Engineering Trimetric TM-2030-RV Battery Monitor System | $155 |

| 1pc | Bogart Engineering Deltec 500 amp, 50 millivolt current shunt | $27 |

| 1pc | Square D Pull-Out Disconnect Switch 60A Not Fusible - UFP222R | $26 |

| Total | $1733 |

Table 1. Recommended solar components, quantities and approximate cost

To understand how the system works, lets start with the 4 solar panels on the right side of the diagram. The way they are connected is pretty much dictated by the way the charge controller is designed and the battery voltage. The charge controller is of a PWM design, which stands for Pulse Width Modulation. That's a fancy way of saying the charge controller acts as an on/off switch for charging the batteries. When the battery voltage is low, it will be on most or all of the time. As the batteries become fully charged, the switch will be off most of the time only providing the power needed to keep the batteries in the fully charged or float condition. The 4 panels are each able to produce around 17-18VDC under no load condition, which is a good thing because more voltage might not be good for the batteries. They are connected in parallel with their positive terminal at the top of the diagram and negative terminal at the bottom, which acts as system ground. The positive lines are brought together in the disconnect which has two lines in and out. One side of the disconnect disconnects the solar panels from the charge controller while the other side disconnects the battery from the charge controller. This allows one to safely shut down battery charging for installation or maintainence. A fused disconnect provided additional protection, but I have to admit I'm currently using an unfused disconnect like the one listed in the table.

Battery charging is accomplished by current flowing out the left side of the disconnect into the battery, down through the shunt resistor, Rs and back into the solar panels. At first blush, putting a resistor in series with the battery might not sound like a very good idea. But the shunt resistor allows the charge controller and battery monitor to keep track of how much current is actually flowing through the battery. This allows them to determine the batteries current state of charge at all times in order to optimize battery charging. The shunt resistor is a very precise low resistance component, 0.0001Ω for those of a technical bent. Hence the charge controller and battery monitor has connections to both sides of the shunt resistor to measure the voltage drop across it. So the charge controller is basically acting as an on/off switch between the positve battery terminal and the positive solar panel terminal that uses battery voltage and current measurement to optimize battery charging.

The battery monitor is the human interface to the system telling one the battery voltage, battery current and percent of charge. Deep cycle batteries should never be discharged below 50% of their capacity if you want them to last a long time. So if your batteries are getting low, it might be a good idea to put your electic coffee pot away until they've been recharged. Many folks try to skimp on cost and not include a battery monitor. I can tell you from experience, this can be a costly mistake. Our RV system didn't have one initially and I wasn't able to tell that my batteries were being undercharged everyday and it only took me 2 yrs to kill a $600 set of batteries. But it actually turned out to be a blessing, as I met Handy Bob and put the system back together the way it should have been in the first place. That was in 2009 and it's still going strong today.

Inverters are connected to the positive battery terminal, through a 60A fuse which in this case is connected to the bottom of the shunt resistor. This allows the charge controller and battery monitor to keep track of the batteries current state of charge. The recommended inverter is a small 300W full sinewave invertor able to run a number of small loads. We used it 99% of the time to run our electronic gizmoses. However, if one intends to run large power devices like power tools, coffee makers or things in general requiring more than 300W a second high power invertor is required. Our RV has a 2000W inverter for this purpose that wasted an Amp or 2 just setting there doing nothing. The smaller inverer was an afterthough, but we could go for weeks without using the big one and wasting the Amps. It's also important to remember that inverters have a surge capability for starting thing that take a little extra power to get them going. The surge capability of the 300W inverter is 600W, for a short period of time, which is why the fuse protecting it is 60A. The fuse has to be able to handle the surge.

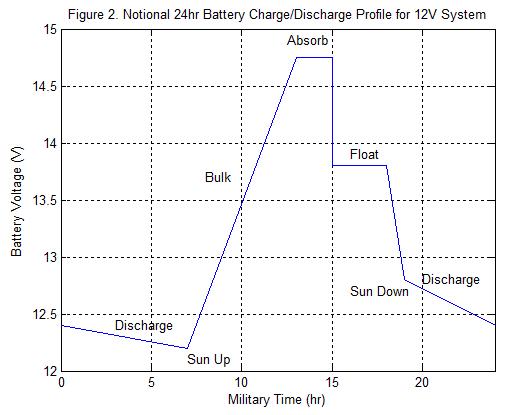

To get a feel for what the charge controller is doing over the period of a day, consider the notional floated lead acid battery voltage vs time curve shown in Figure 2. Time starts at midnight when the battery has already been discharging since sun down. The discharge continues until sun up when the solar panels once again start producing power. The charge controller attempts to recharge the battery as quickly as possible by routing all available power to the battery. This phase of the process is referred to as Bulk charging. As Bulk charging continues throughout the morning, the battery voltage slowly increases until the battery is roughly 100% charged. At this point the charge controller starts throttling back the power going into the battery by holding the voltage around 14.7-14.8V for floated lead acid batteries on a 70°F day. This stage is called Absorb and it's purpose is to slightly overcharge the battery. The Absorb phase helps insure all battery cells are fully charged and returns sulfites that have percipitated out of the solution back into solution. Absorb usually takes around 2 hrs, at which point the battery is fully charged and the charge controller drops the voltage to a level that allows the battery to remain fully charged. This is called the Float phase during which the charge controller attempts to supply all system power needs from the solar panels. It's no longer able to do this as the sun goes down and the battery once again starts discharging until sun up the next morning and the process starts all over.

Now some folks may say they don't care about all this Bulk, Absorb and Float technical mumbo jumbo. They just want solar and will be glad to leave all that to the geeks. Well the unfortunate fact of the matter is when you install your system, the last step before flipping the switch on is that you'll be required to define for the controller what the Absorb and Float voltages you'd like it to use are. In addition, you'll also have to tell it how long to remain in Absorb among other things. So the manufacturer is assuming he sold his stuff to the geek and the geek will set it up properly. A word to the wise. Ya need to understand this if you're gonna do solar!

One system that seemed to work plus solar wiring diagram:

Installation Guidelines and Considerations

We spent 4yrs living full time in an RV with a 400W array of solar panels and 4 golf cart batteries connected into a 12VDC battery bank. A substantial part of our time was spent living off grid or boondocking as the RV'ers like to call it. We attempted to maintain our batteries using the procedure recommended by the company president that made the charge controller we had and 2 years later we had 4 dead golf cart batteries. We thought we'd done everything humanly possible to make them last for 6-10yrs and suddenly realized something was very wrong. Eventually we discovered that solar equipment manufacture marketing is light years ahead of their engineering for most companies and installers.

Solar installations run at low DC voltages and high currents unlike the 120/240VAC found in most homes. That means little voltage drops due to small wire size or poor connection can really add up fast to sap the energy you're getting from those panels. In addition, we discovered charge controller manufactures are worried about being sued by folks who don't maintain their batteries so they set the absorb charging voltage to around 14.3-14.4VDC. Battery manufactures will tell you 14.7-14.8VDC absorb voltages are required to maintain a 12V battery. That little 0.4VDC difference may not sound like much, but it had destroyed our batteries in only 2yrs. The voltages don't cause sulphates that percipitate out of solution to be driven back into solution. Over time they build up at the bottom of each cell and destroy it. You'd think installers would know all this and set the charge controller up to charge at the higher voltages, but sadly most are only interest in separating you from your money as quickly as possible and all that setup stuff takes time they could be spending separating the next customer from their money.

Fortunately, we met up with a fellow fulltime boondocker and solar expert named Bob who helped us sort out the mess. Turns out poorly designed or manufactured components, along with shoddy installation practices is so common in the solar industry that Bob had made a full time job of cleaning up other installers messes. The fact that our batteries were history after only 2yrs was a sure sign we'd been constantly undercharging them and Bob recommended a reliable cost effective replacement for our charge controller. He told us to get new batteries in Yuma and meet him at his work site in the middle of the desert. Turns out the batteries were wired incorrectly, one of the wires connecting the panels to the batteries hadn't been tightened and the long wires between the batteries and the charge controller was inducing addition undesirable voltage drops causing yet more under charging. Bob added a battery monitor to our system, redid the wiring, replaced the charge controller and hooked the batteries up correctly. The whole process took about a day of his time and it's all been working for 6yrs now. If you're interested in Bob's blog where he goes over the pitfalls he's uncovered over the years and the components he's been impressed by, take a look at http://handybobsolar.wordpress.com/.

So I'll try to summerized some of the things I've learned about solar from guys like Bob. I'm sure my list isn't exhaustive by any means, but many of these things came via the school of hard knocks.

- Make sure your system is charging your 12V batteries for an hour or two each day at 14.7-14.8VDC during the absorb portion of the charging cycle. Scale this up for 24 and 48V systems.

- Make sure your charge controller is mounted as close electrically to the battery as reasonably possible. Long wires between controller and batteries will create voltage drops preventing the batteries from seeing 14.7-14.8VDC. If long wires are required somewhere in your system, put them between the solar panels and the charge controller.

- Make sure wire sizes are large enough to minimize voltage drops in your system. For example, the system in the preceeding section uses a 300W inverter to produce 120VAC. A 1V drop in a 120V circuit do to poor wiring is undesirable, but certainly not the end of the world. But in order for the inverter to produce 300W of 120VAC driving a 2.5A load, it has to extract 25A from your 12VDC battery. A 1V drop in the 12V portion of the circuit would be devisating and represent a power loss of almost 10% wasted in wiring. Worse, it could also cause excessive inverter heating and might even cause the inverters low voltage protection to shut it down. Web sites like http://www.csgnetwork.com/voltagedropcalc.html and http://www.cossin.com/page4.html can be used to evaluate wire sizes. But remember, their standard is for not creating a fire hazard, not minimizing voltage drops. Consider their recommendations as the absolute minimum sizes to prevent fires. Not what you should be using. If their site indicates large voltage drops at maximum currents, experiment with increasing the wire size until more managable voltage drops are idicated.

- Make sure your system has a battery monitor like the one in the previous section. You can do serious damage to your batteries if you don't know what's going on with them and you should never discharge them below 50% of their capacity if you want them to last. If you don't know what the current percent of charge is, how are you going to tell when you're getting close to 50%?

- Make sure your batteries are connected properly. There is a right way and a wrong way to configure 4 golf cart batteries into a 12V battery bank. The correct way is shown in the following figure. Notice how current has to go the same electrical distance through the battery bank no matter which battery it goes through. If you don't do this, batteries on the short path will be constantly overcharged while those on the long path will get undercharged. Over time, the long path undercharged batteries will die.

- Another question to consider, is where to mount your panels? This might seem a simple matter, but unless you're blessed with limitless open spaces, shaddows can be a big problem. Our property has lots of trees and we had to study the shaddows for an entire year (through all 4 seasons) to figure out where to mount them. The cabin is surrounded by tree, so that wouldn't work and winter tree shaddow made the choice look like mission impossible. But eventually we realized that if we could get them off the ground far enough the north edge of the clearing near the cabin would work. So we built a small tall barn and mounted the panels on the roof. This also allowed us to make sure the side of the barn was perfectly aligned with north and south. And I'm not talking about magnetic north/south. I'm talking about true north that one discovers by finding the North Star in the night sky.

- Even small shadows can be a big problem. Something as insignificant as a radio arial shadow can shut a panel down. If you have panels in parallel, this might result in slightly low solar output as the remaining panels are left to carry the load. But if they're all in series, one shaded panel can shut the whole string down.

- Panels can be wired in series or parallel if you have the correct controller. Serial connections usually requires an Maximum Power Point Tracking (MPPT) controller, which acts as a DC-to-DC converter to match high panel voltages to lower battery voltages. The advantage of serial panel connections is that it increases the voltage applied to the controller and reduces the current required to achieve the same power level. Reduced cable currents helps minimize voltage drops in the system and can allow you to use smaller gauge wiring. The panels on our barn are wired with four panels in a row, then each row is connected in parallel. This provides around 120DVC to the charge controller when the sun is shining. If you're using high voltages like this, be careful because touching it is at least as bad as sticking your finger in an electrical outlet.

- Once you know where your panel will be located, there's the question of what angle to mount them at. That is unless you have the financial resources to employ sun tracking, which few do. The simple answer is they should be tilted up to match your latitude if you want optimum performance on the solar equinox. The latitude of our property is 45°, so one might suspect that's the angle we chose for our barns' roof. But the optimum angle changes with the season. It's 15° lower at the suns' high point in summer and 15° higher during the shortest day when the pagans celebrate the birth of the sun god. While summer days are long with lots of sun, winter days are rather short with limited opportunities to collect sunshine. We chose an angle slightly less than 60° for our roof pitch to give us the best chance of getting a full charge on those short winter days. During the summer, long daylight hours more than make up for the losses due to poor angle choice. But even with the optimum winter angle, we still find we have to run our generator 6-7 times each winter to make it through those period when cloudy skies for days on end exhausts our battery bank. So for folks who have to rely on solar for winter power, I recommend they mount their panel a little less than their latitude + 15° to optimizes winter performance.

- Now that you know where to mount your panels and at what angle, you might want to think about what you're going to do when it snows if you live in that part of the country. Sure, the snow will eventually melt and allow you to charge your batteries, but can you stand the loss of battery charging time during the shortest days of the year. We couldn't without a lot more generator time, so we built a catwalk on our barn to knock the snow off first thing in the morning. Make sure you know what you'll do when it snows.

- All batteries require periodic attention if you're going to maintain them and flooded lead acid batteries have to be refilled with distilled water. We do this quarterly for our RV and every other month for our cabin system. Maintenance should only be performed when the batteries are fully charged, as refilling uncharged batteries can cause them to overflow when they're brought up to full charge. It's a good idea to check the acids' specific gravity to make sure all cells are reaching the same state of charge. Wildly fluctuating readings indicate your batteries may need to be equalized. If this doesn't help, your batteries may be going bad. Make sure you clean up any battery corrosion while you're servicing them.

- Batteries contain hazardous chemicals and create hazardous gases so they need to be kept in a vented location where they won't cause damage. For our RV there's in a compartment with a metal grating under them to allow free flow of air. We built a fiberglass lined wooded box for the ones in our cabin with a tight lid. We drilled a hole in the lid and have a 2” PVC pipe to allow battery fumes to vent up the pipe to the outside of the cabin. The pipe has to be removed before we can perform battery maintance.

A final installation note. Modern charge controllers, battery monitors and inverter/chargers all have processors in them that have to be configured for you specific installation needs. Don't just assume the manufacture set them up the way you need them. You have to program them.

What to do when the Sun don't Shine

Home Sized Solar System

Solar System Sizing

P3 P4400 Kill A Watt Electricity Usage Monitor - The cheapest watt of electricity is the one you never use. Before building a solar system, make sure you have energy efficient appliances. It will be cheaper to upgrade an appliance then to build a solar system to handle inefficient appliances. The best way to determine how much electricity an appliance is using is with a Kill a Watt Electricity Usage Monitor

Plug the Kill a Watt into the wall outlet, plug appliance into the Kill a Watt. Let it run for about a week, the length of time does not have to be exactly one week, just needs a long period of time. At the end of one week push the right red button. It toggles between kilowatt hours and time. The time is in hours. Divide the kilowatt hours by the time and multiply by 24 to get average kilowatt hours per day for that appliance. Do this for each appliance you may want to power with solar.

Manage the usage - This is a humorous example of the importance of managing electric use when you have a limited source. http://www.imdb.com/video/hulu/vi2444560153/?ref_=tt_ov_vi

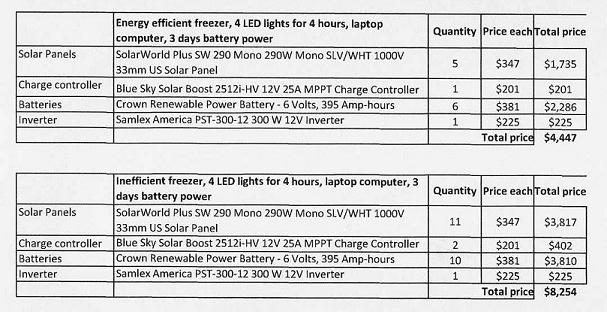

A energy efficient chest freezer uses about .7 kilowatt hours per day. Four 9 watt LED lights used four hours will use about .3 kilowatt hours per day. My laptop computer uses about .7 kilowatt hours per day. The inefficient freezer uses about 2.4 kilowatt hours per day.

The following are the components used in these examples to build a small 12 volt solar system. The price estimates do not include a frame for the solar panels, wires, breakers, combiner box, battery box and connectors.

Solar panels - SolarWorld Plus SW 290 Mono 290W Mono SLV/WHT 1000V 33mm US Solar Panel $347 each

Charge controller - Blue Sky Solar Boost 2512i-HV 12V 25A MPPT Charge Controller $201 each

http://www.civicsolar.com/product/blue-sky-solar-boost-2512i-hv-12v-25a-mppt-charge-controller

Batteries - Crown Renewable Power Battery - 6 Volts, 395 Amp-hours $381 each

Inverter - Samlex America PST-300-12 300 W 12V Inverter $225 each

http://www.civicsolar.com/product/samlex-america-pst-300-12-300-w-12v-inverter

Batteries are the most expensive part of the system. Solar panels keep getting cheaper over time but unfortunately batteries do not. Batteries are needed for night time and for cloudy days. These estimates assume that there will be at most three cloudy days in a row. That is the minimum. Allowing for more cloudy days would require more batteries and more solar panels to charge the additional batteries.

The following spreadsheets are to give you a ballpark idea of the costs. They are not meant to be complete systems. Consult an experienced person before you take the plunge into solar.

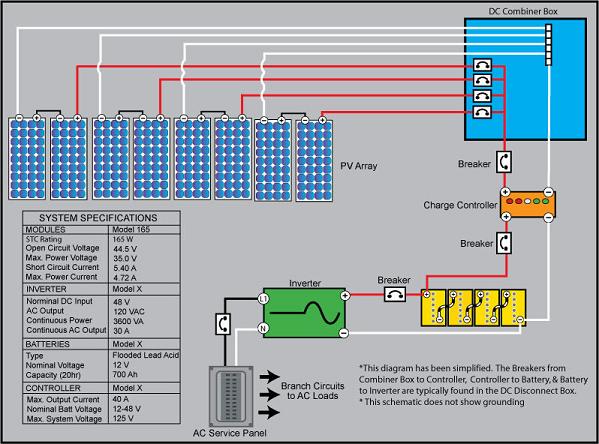

The following diagram shows the wiring of a sample 48 volt solar electric system. It is not based on the components listed above but is intended to show how solar electric system components are connected.